Research Article - Der Pharma Chemica ( 2017) Volume 9, Issue 4

Postharvest Treatments to Prolong Marketable Period and Keeping Fruit Quality of Costata Persimmon

Omaima M Hafez*, Malaka A Saleh, Khafagy SA and Maksoud MAOmaima M Hafez, Pomology Research Department, National Research Centre, Dokki, Cairo, Egypt,

Abstract

Persimmon cv. Costata fruits were used to investigate control decay, delay fruit ripening and keeping their quality and extending marketing period (shelf life). Fruits were dipping in the solution of acetyl salicylic acid (ASA) levels 2, 3 and 0% as control. Selected fruits stored at room temperature “warm storage” 26.3 ± 1.4ºC and relative humidity (RH) 45 ± 2% for 45 days. Results showed that fruits ASA treated prevent decay (%) up to 30 days of warm storage and had more effective to reduce the percentages of weight loss and decay as well as increasing total soluble solids, tannins and β-carotene and decreasing total acidity, firmness and ascorbic acid. The most effective treatment in reducing losses of persimmon fruit quality was found to be high level ASA treatment during the hot storage period. It was determined that under these conditions Costata Persimmon can be stored for 45 days without losing much of its quality.

Keywords

Costata Persimmon, Warm temperature, Acetylsalicylic, Vitamin C, β-carotene, Total tannins

Introduction

Persimmon (Diospyros kaki L.) is deciduous fruit, the most widely cultivated species of the genus Diospyros, commonly cultivated in warm regions of the world. Also, it is one of the most nutritious fruits bestowed with strong antioxidant activity [1] having a great mystical power that can be harnessed to solve headaches, back pains and foot ache. So, its demand is increasing owing to consumer's awareness regarding its hidden health promoting potential. Persimmon Costata cultivar is the main and leading that consumed in the Egyptian market. It’s ripening differently than other fruits. Really hard persimmons to ripen so expect to wait for several weeks for ripe. Immature persimmon fruits have a high proanthocyanidin-type tannin content which makes the immature fruit astringent and bitter [2]. The tannin levels are reduced as the fruit matures. Placing that persimmon in sunlight will remove the tannins very quickly [3]. Persimmon ripening is regulated by ethylene. During climacteric stage, rapid softening occurs resulting jelly-like flesh thus makes persimmon unmarketable within a few days. Thus, persimmon crop harvested at commercial maturity produces less ethylene production than that harvested at early mature stage releases higher amounts of ethylene [4]. The eating quality of persimmon is considered best at the end of the pre-climacteric stage owing to presence of maximum sugars and desired orange color [5,6].

Chemical treatments have been used to prevent insect attack and prolong postharvest shelf-life. Salicylic acid (SA) is considered as a plant hormone [7], inhibiting ethylene biosynthesis and delaying the fruit senescence [8] it considered as safe for food and environmental [9]. The pattern of decrease in endogenous SA level was related to accelerated softening while the application of acetylsalicylic acid (ASA) (a derivative of SA slowed down the softening rate of kiwifruit by inhibiting ethylene production and maintaining higher endogenous of SA levels [10].

In the last decade, there has been increasing interest in the use of heat treatments to control insect pests, prevent fungal rots, increase resistance to chilling injury, delay fruit ripening, and extend postharvest shelf-life of fruits [11]. Heat treatments have been shown to inhibit fruit ripening and improve post-storage quality of fruit including apple [12], citrus fruit [13] and mangos [14]. Thus, heat treatment has potential for the commercial control of ripening of harvested persimmon fruits [3,15].

The main postharvest problems of persimmon are severe softening and disease incidence on the fruits during storage. Therefore, delay in softening and/or control of diseases result in the storage life extension of persimmon fruit. Thus, the target of this study was using three concentration of acetylsalicylic (0.01 and 3%) under room temperature (hot storage) to control decay, delay fruit ripening of persimmon cv. Costata for keeping their quality and extending marketing period (shelf life).

Materials and Methods

Plant sample

Costata Persimmon fruits (Diospyros kaki L.), an astringent persimmon cultivar, were harvested from a private orchard located at Kalubia Governorate Egypt, at commercial maturity stage and coloring (two thirds of the surface) at October 2015. Greenish-yellow color maturity fruits were selected undamaged, uniformed in shape, freedom from blemishes, pathogen infection, and immediately transferred to the laboratory of Agriculture Development Systems (ADS) project in the Faculty of Agriculture, Cairo University.

Treatments and storage condition

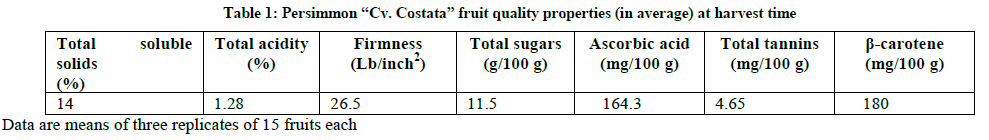

The fruits were divided into three groups and were treated by dipping in the solution of ASA 0 (as control), 2 and 3% for 5 min. Every treatment has five replicates, every replicate contained 6 fruits. Treated fruits were air-dried, both replicate per treatment were packed in fiberboard cartons and stored at room temperature warm storage 26.3 ± 1.4ºC and Relative Humidity (RH) 45 ± 2% for 45 days, 15 random fruits of each treatment (as 3 replications each of 5 fruit) were transported to the laboratory of food industry, National Research Centre-Dokki Giza-Egypt, to determined fruit quality measurements at the end of study. The initial quality measurements were determined as shown in Table 1.

Fruit quality assessments

Physical characters

Weight loss: Fruits were periodically weighed and the loss in mass weight was recorded for each replicate. Data were calculated as percentage from the initial weight. Decay percentage: Fruits which were decayed by different physiological and pathological factors were periodically counted and discarded. Then percentage of fruits was calculated in relation to the total number of fruits. Fruit firmness: Was determined as Lb/inch2 by using fruit pressure tester model FT 327 (3-27 Lbs), were determined at the end of warm storage.

Chemical characters

Chemical properties were measured at the end of warm storage periods (after 45 days) such as: Total soluble solids percentage (TSS %): by using hand Refractometer. Total acidity (TA %): was estimated as percentage of Malic acid in fruit juice [16]. Total Sugars (g/100 g FW): was determined using the phenol and sulphoric acid [17]. Ascorbic acid (mg/100 g): Determination of vitamin C [16]. Total tannins (mg/100 g): Were determined by Folin-Ciocalteu method according to Miean and Mohamed [18]. β-carotene (mg/100 g): Carotenoids were extracted according to Moore et al. [19]. HPLC analysis was performed using Agilent 1100 HPLC system (Agilent Technologies, Palo Alto, CA). Separation was accomplished using an ODS C18 column and a mobile phase of CH3OH:CH3CN:CHC13 (47:47:6). The flow rate was set at 1 ml/min and all readings were taken at 461 nm.

Statistical analysis

The data were subjected to statistical analysis using computer based software “MS-Excel” and results were submitted to analysis of variance [20]. Differences among treatment means were determined by using the LSD test at a significance level of 0.05 [21].

Acknowledgments

Authors wish to thank the late Dr/Mamdouh Mohamed Nageib, Pomology Professor, and National Research Center (NRC), to provide fruits under study. We are also thankful to Food Technology Department (NRC) for helps in the chemical analysis. Also, we thank the members of Agricultural Development Systems project (ADS) for technical assistance.

Conclusion

This study has shown that a warm storage and ASA treatments has the potential to control the ripening of Costata Persimmon fruits. It’s significantly delayed the onsets of climacteric ethylene production in persimmon fruits. Also, these significantly retarded the increase in carotenoids content, TSS and decrease in firmness, TA, Weight loss and decay.

In conclusion, the research indicates that warm storage and ASA concentration treatments are effective methods of extending the marketable period of persimmon in warm storage (26.3 ± 1.4ºC) and 45 ± 2% relative humidity (RH) up to 45 days. The most effective treatment in reducing losses of fruit quality was found to be high level ASA treatment during the storage period of persimmon. It was determined that under these conditions Costata persimmon can be stored for 45 days without losing much of its quality.

References

[1] M. Igual, M.L. Castello, M.D. Ortola, A. Andres, J. Food. Eng., 2008, 86, 315-323.

[2] T. Matsuo, S.A. Itoo, Agric. Biol. Chem., 1982, 46(3), 683-689.

[3] Z. Luo, Eur. Food. Res. Technol., 2006, 222(1), 149-154.

[4] S. Harima, R. Nakano, S. Yamauchi, Y. Kitano, Y. Yamamoto, A. Inaba, Posth. Biol. Technol., 2003, 29, 318-323.

[5] Q.L. Zheng, A. Nakatsuka, S. Taira, H. Itamura, Posth. Biol. Technol., 2005, 37, 190-286.

[6] L. Arnal, C. Besada, P. Navarro, A. Salvador, J. Food. Sci., 2008, 73, S26-S30.

[7] I. Raskin, Annu. Rev. Plant. Physiol. Plant. Mol. Biol., 1992, 43, 439-463.

[8] O. Khademi, Z. Zamani, Y. Mostofi, S. Kalantri, A. Ahmadi, J. Agric. Sci. Technol., 2012, 14, 1067-1074.

[9] L. Hooper, A. Cassidy, J. Sci. Food. Agric., 2006, 86(12), 1805-1813.

[10] Y.U. Zhang, C.K. Song, C.Q. Jun, Z.S. Long, R.Y. Ping, Acta. Botan. Sinica., 2003, 45(12), 1447-1452.

[11] S. Lurie, Posth. Biol. Technol., 1998, 14(3), 257-269.

[12] J.D. Klein, S. Lurie, J. Am. Soc. Horti. Sci., 1990, 115, 255-259.

[13] R. Porat, D. Pavoncello, J. Peretz, S. Ben-Yehoshua, S. Lurie, Posth. Biol. Technol., 2000, 18, 159-165.

[14] K.K. Jacobi, J.E. Giles, Posth. Biol. Technol., 1997, 12(3), 285-292.

[15] L. Arnal, M.A. Del Río, Spanish. J. Agricult. Res., 2004, 2(2), 243-247.

[16] AOAC International, Washington D.C., USA, 2000, 1080.

[17] F.A. Smith, M. Gilles, K.J. Haniltun, A.P. Gedees, Anal. Chem., 1956, 28, 350.

[18] K.H. Miean, S. Mohamed, J. Agric. Food. Chem., 2001,49, 3, 106-3112.

[19] J. Moore, Z. Hao, K. Zhou, M. Luther, J. Costa, L. Yu, J. Agric. Food. Chem., 2005, 53, 6649-6657.

[20] G.W. Snedecor, W.G. Cochran, Press. Ames. Iowa, USA, 1980, 507.

[21] R.A. Waller, D.B. Duncan, J. Amer. Stat. Assoc., 1969, 64, 1484-1503.

[22] D. Lydakis, J. Aked, Posth. Biol. Technol., 2003, 27(2), 117-126.

[23] H. Zhang, L. Ma, L. Wang, S. Jiang, Y. Dong, X. Zheng, Biol. Control, 2008, 47, 60-65.

[24] X. Xu, S. Tian, Posth. Biol. Technol., 2008, 49, 379-385.

[25] K.K. Jacobi, E.A. MacRae, S.E. Hetherington, Posth. Biol. Technol., 2000, 21, 39-49.

[26] K.L. Rossiter, H. Young, S.B. Walker, M. Miller, J. Sens. Stud., 2000, 15, 241-250.

[27] K. Marsh, K. Rossiter, K. Lau, S. Walker, A. Gunson, E.A. Macrae, Acta. Hort., 2003, 610, 229-237.

[28] S. Namdar, M. Ozcan, In: R. Gercekcioglu (Editor), II. Small Fruits Symposium Tokat, Turkey, 2006, 14-16, 348-353.

[29] E. Bal, S. Celik, Bulg. J. Agri. Sci., 2010, 16(5), 576-584.

[30] W.S. Conway, C.E. Sams, C.Y. Wang, J.A. Abbott, J. Am. Soc. Hortic. Sci., 1994, 119, 49-53.

[31] S.H. Zhu, L. Sun, J. Zhou, Int. J. Food Sci. Technol., 2010, 45, 245-251.

[32] E. Ardakani, G.H. Davarinejad, M. Azizi, J. Hortic. Sci. (Agricult. Sci Technol.), 2013, 26(4), 448-459.

[33] S. Sharma, Ph. D. thesis, IARI, New Delhi, India, 2014.

[34] S.V.R. Reddy, R.R. Sharma, Indian. J. Agr. Sci., 2016, 86(6), 727-731.

[35] Y. Tatsumi, Bull. Facult. Agr. Miyazaki. Univ., 2000, 47, 59-68.

[36] D. Ragazzini, In: El kaki. 3th Edn., Ed Mundi Prensa, Madrid, Spain, 1985, 59-132.